-

QUICK VIEW

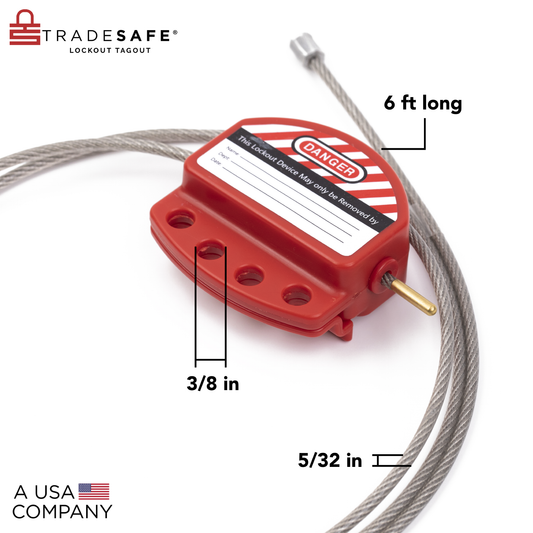

- 5/32” diameter PVC-coated multi-stranded flexible stainless steel cable lockout

- Hardwearing ABS body

- High-grade brass cable end for convenient threading

- Accommodates up to 4 LOTO locks

Adjustable Cable Lock Out Device - 6ft

Regular price $17.98Regular priceUnit price per$36.00Sale price $17.98Sale -

QUICK VIEW

- 5/32” diameter PVC-coated multi-stranded flexible stainless steel cable lockout

- Hardwearing nylon body

- High-grade brass cable end for convenient threading

- Accommodates up to 5 LOTO locks

Adjustable Cable Lock Out Device - 10ft

Regular price $29.90Regular priceUnit price per$65.00Sale price $29.90Sale -

QUICK VIEW

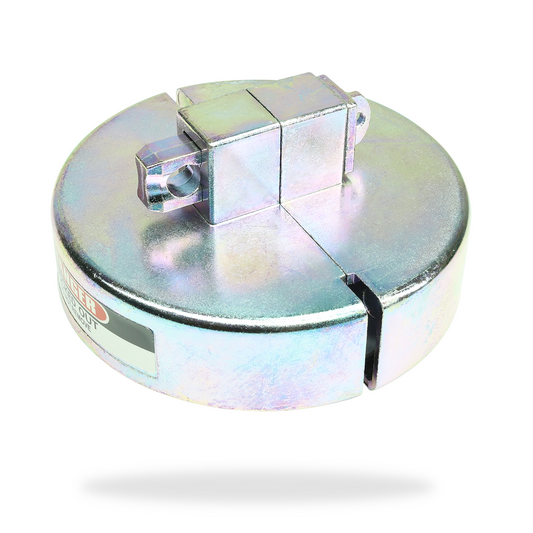

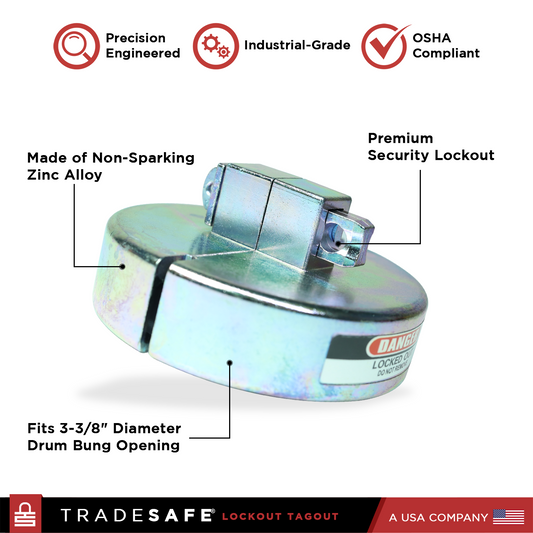

- Covers bung opening/clamp lids; no need to remove original seal plug

- Corrosion-resistant, non-sparking zinc alloy drum lock set

- Locks out standard 55 gallon metal or plastic drums

- Secure using 1 safety padlock with 1/4” shackle diameter

Drum Lock - Fits 3-3/8” Diameter Drum Bung Opening

Regular price $18.95Regular priceUnit price per$36.00Sale price $18.95Sale -

QUICK VIEW

- Industrial-grade nylon and tough rubber gasket

- Drum lock for drum bunghole, pipe opening, and others

- Two resilient gaskets included expanding from 2-3/16” to 2-3/8" and 2-3/8" to 2-3/4" diameter

- Secure using 1 safety padlock with 3/8” shackle diameter

Nylon Drum Security Plug With 2 Rubber Gaskets

Regular price $15.95Regular priceUnit price per$31.50Sale price $15.95Sale -

QUICK VIEW

- Locks out large or oddly-shaped controls

- Tear-resistant polyester canvas

- Tamper-resistant PVC vinyl interior lining

- Striking red lockout bag for high visibility

- Secure with up to 3 LOTO locks

Oversized Plug and Hoist Control Cover, 17-1/4” x 10”

Regular price $24.95Regular priceUnit price per$100.00Sale price $24.95Sale -

QUICK VIEW

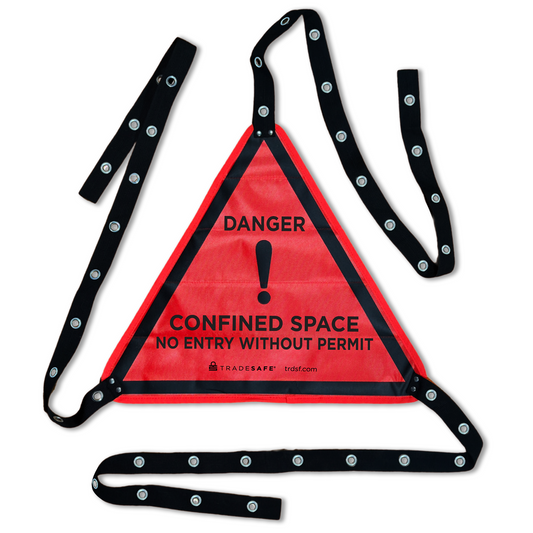

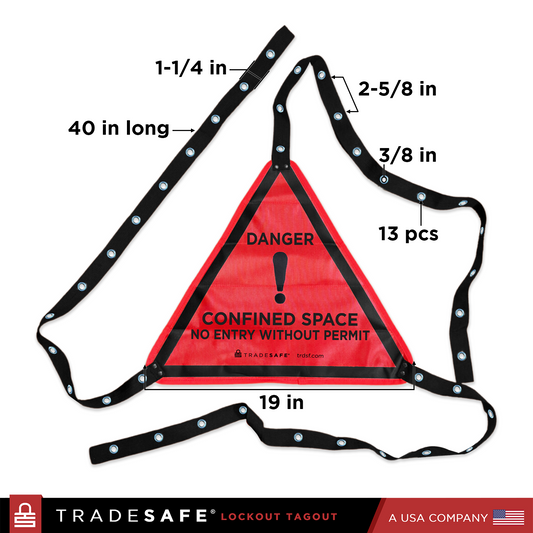

- Rugged 19” polyester confined space cover

- 40" resilient straps on each side, each equipped with 13 solid grommets

- Designed with a triangle shape & red color indicating danger

- Locks out manholes, tanks, silos, tunnels, and more

Confined Space Cover

Regular price $39.95Regular priceUnit price per$75.00Sale price $39.95Sale

LOTO Devices

Some facilities have needs that are more specific or specialized compared to the needs of others. TRADESAFE provides precision-engineered lockout tagout devices that can help address your specific needs and concerns.

Here you’ll find electrical plug lockout devices, cable locks, hasps, valve LOTO devices, and more. Each device is made of durable and high-quality materials that are capable of withstanding the harsh conditions of industrial facilities. Additionally, these devices are easy and uncomplicated to use, but they can help ensure safety in your facility.

Find the right lockout tagout device for your specific needs. No need to worry about quality; all these devices are guaranteed to give you good value for your money.

FAQ

What requirements apply to lockout tagout devices?

OSHA has a few special standards for lockout tagout devices that differ significantly from regular padlocks and common products. Lockout tagout devices must be designed according to precise requirements in order to be OSHA compliant. TRADESAFE carefully evaluates these critical needs and works hard to guarantee that all products meet or surpass such standards.

Therefore, the following features should be included in these devices:

Durability – Lockout tagout devices must be made of materials that can withstand corrosive substances, impact, extreme temperatures, chemicals, water, and more.

Standardized Characteristics – The color, dimensions, shape, and other features of the devices should be standardized. This includes tags, whose print and format should also be standardized. Additionally, the instructions on the tags have to be clear and easy to read.

Substantiality – The devices must not be easy to remove or destroy. Only the use of excessive force should be able to remove the devices when necessary. Even tag attachments should be able to withstand all sorts of environments.

Proper labels – All lockout tagout devices used in a company’s lockout tagout procedures should be labeled appropriately. The labels should clearly identify the employees that installed the locks.

What does de-energization mean?

The process of de-energization entails isolating machinery, equipment, or systems from a source of energy. In lockout tagout, however, de-energization does not mean simply unplugging a machine; it means preventing the accidental or inadvertent re-energization of a machine.

When a machine is de-energized, it should also be properly locked out and tagged out. Lockout tagout entails the use of certain devices that will make the safe de-energization and re-energization of a machine possible.

How do you use valve handle lockout tagout devices?

Gate valve locks are typically designed to be able to cover the entire handwheel of a gate valve. To use one of these locks, simply open it up and fit the two halves over a gate valve’s handwheel. Make sure that the handwheel is in the off position.

You will then have to secure the two halves together with a personal safety padlock. You will also have to attach a tag to warn and provide pertinent information to other employees.

Who keeps the key when you perform lockout tagout?

Where is it best to store lockout tagout devices?

What must be written on lockout tagout tags?

Who can remove Danger Tags?

How do you install a cable lockout device?

Who can perform lockout tagout?

Likewise, only the authorized employees who installed the devices have the authority to remove them. However, there may be times when a lockout tagout device must be removed and the employee who installed it is unavailable. In such cases, the employer must supervise another employee uninstalling the device.

How do you use lockout tagout devices?

Padlocks – Personal safety padlocks are used to secure lockout tagout devices such as valve locks, circuit breaker locks, plug locks, cable locks, and lock boxes. Each padlock belongs to an authorized employee and should be tagged with the owner's details.

Valve locks – Valve locks are used to secure valve handles and are locked with a personal safety lock, preventing employees from physically accessing the handwheel.

Circuit breaker locks – Circuit breaker locks prevent electrical circuits from being accidentally activated. Employees can install them by clamping them over circuit breaker switches. Then, personal safety padlocks must secure these locks.

Plug locks – A plug lock stops a machine from being plugged in, therefore preventing power from flowing into it. The plug lock encases the machine's plug, which is then secured with a padlock.

Cable locks – There are bound to be situations in which a switch or a valve is in a spot that’s difficult to access, making lockout tagout difficult as well. A cable lock is versatile and can be used in hard-to-reach areas, thus making lockout tagout possible.

Tags – Tags are an essential part of lockout tagout and should thus be included with every lock installed. They all come with a tie hole that allows them to be attached to locks. Additionally, they are writable and can be labeled with information about the lockout tagout procedure that’s underway.

Hasps – Hasps are versatile and can be used on lockouts for valves, circuit breakers, and a variety of machines. Each hasp comes with multiple padlock holes that allow multiple employees to lock out a single machine, valve, or panel.

Lock boxes – When personal safety padlocks are currently in use in a lockout tagout procedure, their keys can be stored and secured in a lock box. The lock box itself can also be secured by multiple padlocks belonging to all employees involved in the procedure. This ensures that no machine, valve, or panel will be re-energized until all employees are done with their lockout tagout tasks.People Also Ask

How do you use a plug lockout device?

A plug lockout device keeps plugs from being inserted into an outlet, thus preventing an electric current from re-energizing a piece of equipment while under maintenance or repair. This protects workers from electrical shocks.

To use, open the plug lockout and insert the plug inside the case. There are holes on both ends of the device that fits the diameter of the cord. Close the plug lockout over the plug, secure with a padlock, and tag accordingly. TRADESAFE offers medium and large plug lockout devices that can store up to two plugs.

What are the different types of plug lockout devices?

There are three types of plug lockout devices:

- Plug lockout - This keeps the plug inside and prevents re-energization by disabling the plug from getting inserted into a wall outlet.

- Lockout cinch sack cover - This is primarily used for oddly sized large connectors and hoist controls. This comes with a cinch top to close and holes for padlocks.

- Power cord lockout – Compared to a plug lockout that keeps the plug inside the lockout device, a power cord lockout is directly inserted to the plug itself. It cannot be removed without a key, thus preventing the cord to be plugged into an outlet.